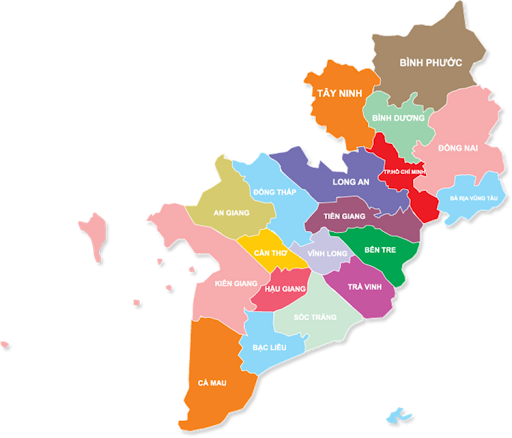

Southern Vietnam comprises 17 provinces and municipalities, covering approximately 77.7 thousand square kilometers, divided into two sub-regions: Southeast and Southwest.

Despite its significantly smaller area compared to the North and Central regions, Southern Vietnam serves as the economic powerhouse of the country. According to data from the General Department of Customs, the Southern region is the largest processing and exporting hub for wood in Vietnam. Southern plywood production features large-scale production capabilities, advanced technological processes, and proximity to high-quality raw materials.

Raw material resources

The Southern region experiences a clear distinction between rainy and dry seasons, with low-lying terrain predominating. These natural conditions are generally not conducive to forest development but are highly advantageous for agriculture and industrial activities

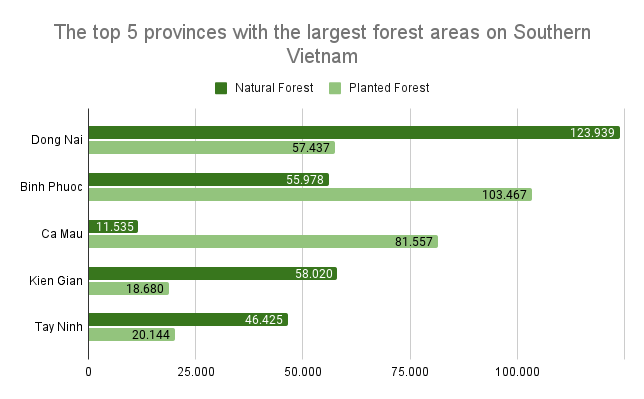

According to the 2022 statistics from the General Department of Forestry, the total forest area in the Southern region is 726,082 hectares, significantly less than that of the Northern and Central regions. In general, the Southern region is not considered an ideal raw material zone.

(Image: Rubber tree logs and core veneer)

However, the South benefits significantly from its proximity to the Central region, especially the Central Highlands, renowned for extensive rubberwood plantations. Despite the Southern region’s limited natural forest resources, it compensates by importing substantial quantities of high-quality rubberwood from the Central Highlands at competitive prices. This strategic advantage supports a robust wood processing industry in the South, where advanced technologies and efficient manufacturing processes transform imported raw materials into high-value wood products.

Major production areas

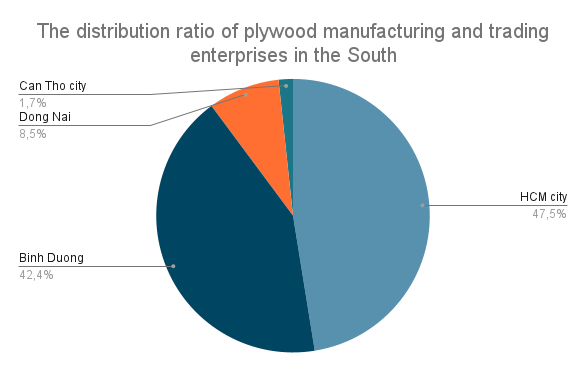

According to statistics from Yellow Pages, plywood production in the South is concentrated in cities such as Ho Chi Minh City, Binh Duong, Dong Nai, and Can Tho City, indicating strategic industrial hubs that leverage the region’s logistical advantages and skilled workforce.

Plywood factories in the Southern region typically operate on relatively large scales, with average areas ranging from 10,000 to 15,000 square meters. Some of the largest factories, particularly in Dong Nai and Binh Duong, cover total areas of up to 100,000 square meters and boast production capacities reaching up to 80,000 cubic meters per month. These large-scale operations benefit from advanced automation and state-of-the-art machinery, enabling high-volume and high-quality plywood production. This scale allows them to efficiently meet both domestic demand and export requirements, contributing significantly to Vietnam’s plywood industry.

Furthermore, the Southern region’s strategic location near major international seaports such as Ho Chi Minh City Port and Cai Mep – Thi Vai Port facilitates efficient export activities, reinforcing its pivotal role in Vietnam’s wood processing and export sectors, driving economic growth and regional development.

With access to extensive raw materials, large-scale production, advanced technology, and a skilled workforce, the Southern region’s plywood industry produces a diverse range of export-standard products at competitive prices.

Characteristics of Plywood Production

The strengths of plywood production in the Southern region of Vietnam include:

- Proximity to raw materials: The Southern region benefits from its close proximity to the Central Highlands, a major source of high-quality rubberwood. This proximity ensures a reliable and cost-effective supply of raw materials essential for plywood production.

- Large – scale production facilities: The large production capacities enable economies of scale, lowering per-unit costs and enhancing competitive pricing. The expansive factory sizes support diverse production lines, offering the flexibility to adapt to market trends and customer needs, which increases market responsiveness and fosters innovation.

- Advanced technological capabilities: Southern factories often utilize state-of-the-art machinery and advanced automation techniques, which enhance production efficiency and product quality.

- Skilled and abundant workforce: The region boasts a skilled labor force experienced in wood processing and manufacturing, contributing to high standards in production.

- Strategic location and logistics: A well-developed infrastructure and logistics network support smooth transportation of raw materials and finished products, enhancing overall supply chain efficiency.

(Image: Plywood Factories and Machines)

However, there are some limitations of plywood production in the Southern region of Vietnam:

- Limited raw material sources: Dependence on external sources can lead to supply chain disruptions and increased costs if there are issues with availability or transportation.

- Infrastructure strain: Overburdened ports, roads, and warehouses can lead to delays and increased transportation costs, affecting the timely delivery of raw materials and finished products.

In conclusion

In summary, plywood production in the Southern region of Vietnam is characterized by its large-scale operations, advanced technological capabilities, and strategic proximity to high-quality raw materials from the Central Highlands.

While it benefits from an efficient supply chain and robust industrial infrastructure, the region faces challenges such as dependence on imported raw materials and environmental constraints. Despite these limitations, the Southern region remains a key player in Vietnam’s plywood industry, excelling in export-standard production and competitive pricing.