1 – What is LVL plywood?

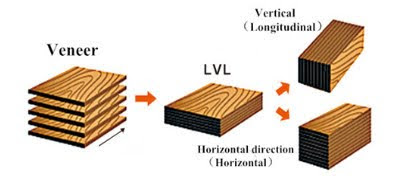

Lvl (Laminated Veneer Lumber) also known as codirected plywood. It is an industrial wood made up of many thin layers (Veneer) that are stacked in the same wood grain dimension and are bonded together through Melamine or Phenolic glue

2 – Applications

LVL plywood stands out for its high uniformity, structural stability and outstanding bearing capacity.

With Vietnamese LVL Plywood is usually usage for doing pallets, box packing

Moreover, higher quality VietNam’s LVL Plywood can produce interiors such as sofa, flush doors, inlaid bedding,…

3 – Compare LVL, plywood?

When looking at the edge of a plywood, it is difficult to distinguish whether it is LVL, LVB or Plywood. Different names, it is clear that the structure must be different, leading to different production technology (pressure, pressing temperature, etc.) will also be different and produce products with different physical and mechanical properties

– Name and structure:

LVL (Laminated veneer lumber): All layers of veneer are arranged parallel and in the same 1 dimension of wood grain

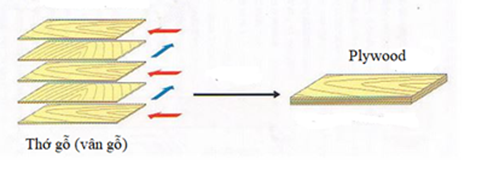

Plywood: Unlike LVL, the veneer panels of Plywood are arranged horizontally and vertically, intertwined with every 1 layer of horizontal veneer to 1 layer of vertical veneer. Because the number of veneer layers is always an odd number, it is ensured that the 2 outermost surface layers of Plywood are always the same grain of wood.

-Characteristics and Application:

Because LVL’s veneer layers are arranged in the same direction, the product has a large bending strength, which is easy to bend, suitable for products that need bending curvature during construction.

In contrast to LVL, Plywood has a greater destructive strength, suitable for load-bearing products such as the inner frame of industrial wooden doors, interior products, etc.

4 – Specifications

|

Character |

Specification |

|

Length |

Up to 5000mm |

|

Thickness |

From 9-95mm |

|

Face/back |

Styrax/Mixed wood/Acacia/Pine |

|

Core |

Acacia, Mixed wood, Pine |

|

Glue |

E2, E1, E0 |

5 – Three common problems when importing laminated plywood (LVL)

Laminated veneer (LVL) is one of the popular wood materials, and it can replace lumber with several advantages. There are also many problems when importing this wood material, especially for the first time.

- Humidity:

This is the most important problem of LVL when it will be transported after a long time in containers. High humidity will cause LVL to become moldy after a long time, especially in many tropical countries. The most preferred humidity is less than 18%, it will keep the LVL dry and reduce the mold rate.

Our Qualified Moisture Content Test

Why does it have this problem?

LVL is made from many thin layers of veneer, and the veneer is oriented in the same direction making it different from plywood. During the manufacture of plywood, adjacent layers of their wood grain rotate up to 90 degrees together. Because all veneer layers are oriented in the same direction, it makes it difficult for LVL to vent during the hot pressing process.

Our Un-Qualified Moisture Content Test

- Delamination:

Delamination makes the LVL weak, and it can be broken when used as framing or pallets. Controlling the delamination rate is one of the most important things in 1 shipment.

- Packaging:

The poor packaging will make the bundle break after a longship. In addition, the pallet block should be high and strong enough to be loaded and discharged by forklift.

HOW TO RESOLVE THESE PROBLEMS?

To avoid these problems, first of all, the importer should understand that these problems may arise in the shipment of LVL and you make it clear with the supplier when negotiating and show in the specification of the product on the sales contract. Choosing the right partner is the most important.

- Moisture Content

The moisture content should be strictly controlled during the production: from raw material, in production, and before loading.

Raw material: control the moisture content of the veneer at less than 20%, it’s better to dry the veneer by force drying method, to make sure that the moisture content of all the veneers is uniform and at the standard

Input Veneer Moisture Content Test

In production: Strictly control the moisture content of the core board after the hot press process and after the cutting process. The standard should be less than 18%, if any board is high moisture content, the producer should bring it to dry immediately.

Pre-cutting LVL board Moisture Content Test

In the packaging process: Before packing the LVL into the pallets, strictly control the moisture of the finished plank, assured that all the plank is at the standard. In case any plank is not qualified, the factory should bring it to dry by sun-dry or drying machine.

Moisture Content Test During Packaging Process

High Moisture Content LVL Sun-Drying

- Quality

The quantity and the delamination rate must be controlled by the factory, thus the worker should be well trained to detect the defect early in the production process.

- Packaging

The bundle should be strapped by the strong metal strap or plastic strap, extra strap with the high bundle.

The height of the pallet block could be at the standard 90mm to lift by forklift and strong enough not to break after a longship.

To minimize all these problems effectively, having a QC team in the factory is the key to having a qualified shipment. QC service is available at all factories, in addition, the QC service will be free when customers purchase from us. For each shipment, our QC team will strictly control the quality from raw material to finished production and loading into the container, and issue the Report at the customer’s request

6 – Vietnam countries are importing LVL plywood

Vietnamese LVL Plywood is popular mainly in countries such as Singapore, Malaysia, Thailand, Japan, Korea,… They are normally used to box machines or pallets.

Kego’s picture of packing LVL container

Overall,

LVL plywood is a flexible and multi-purpose board in Vietnam. We always pay attention to quality before exporting LVL plywood. In the future, Vietnamese LVL plywood will expand even more in the international market.

If you have any questions, please contact us for further advice about this item.