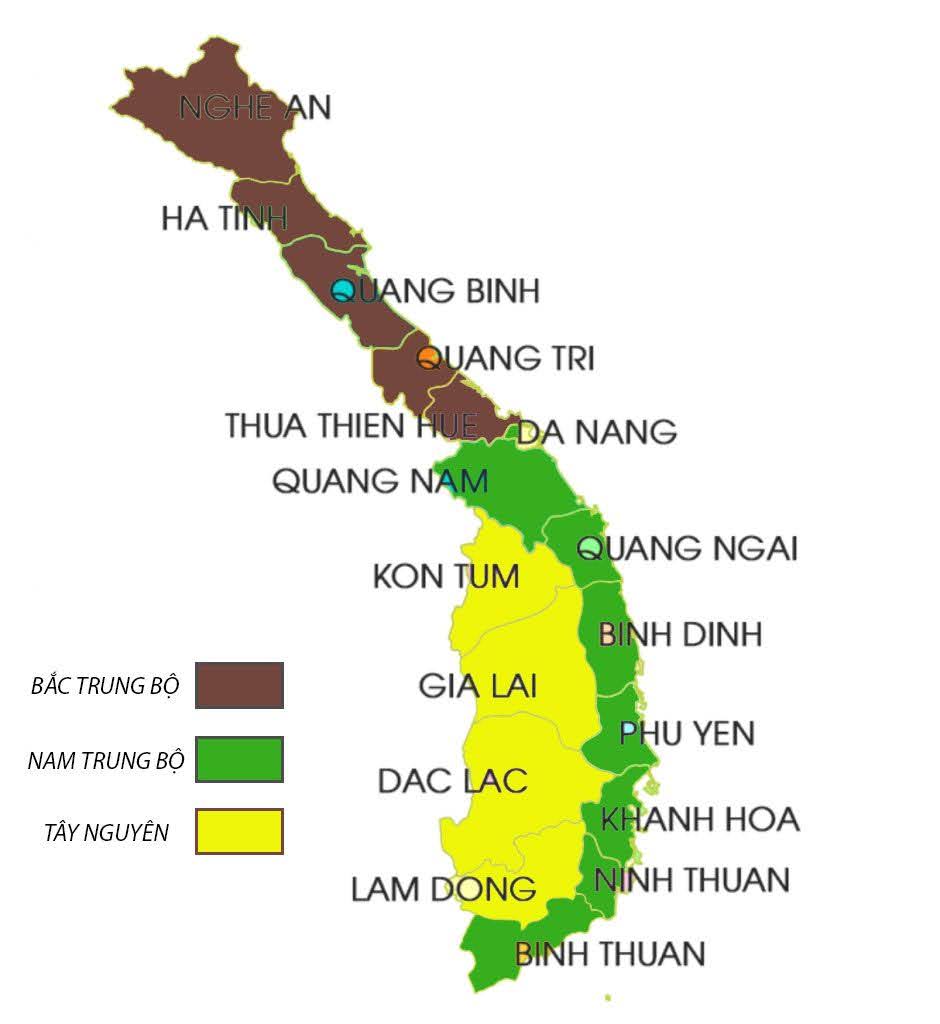

Central Vietnam includes 19 provinces and cities, covering an area of approximately 151,000 square kilometers, divided into three sub-regions: North Central Coast, South Central Coast, and Central Highlands.

The climate and terrain of Central Vietnam are conducive to forest growth but present several challenges for plywood production. Generally, plywood production in Central Vietnam is not as developed as in the Southern and Northern regions. However, this region serves as the largest supplier of raw materials for the wood processing industry in Vietnam.

Abundant raw material resources

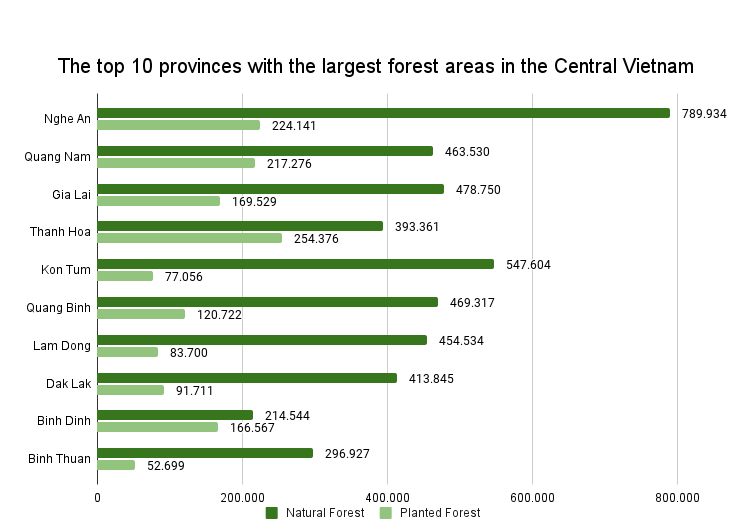

The rugged mountainous terrain, including the majestic Truong Son range, combined with a tropical monsoon climate, creates an ideal environment for the formation and development of forests in Central Vietnam. According to the 2022 statistics from the Ministry of Agriculture and Rural Development, the Central region has the largest forest area in the country, totaling 8,176,903 hectares, with 2,308,341 hectares of planted forests.

The provinces of Nghe An, Quang Nam, Gia Lai, Thanh Hoa, and Kon Tum are leading regions in planting and harvesting wood and timber. They are renowned for their abundant timber resources, supplying core veneer for plywood production in both the Southern and Northern regions. The quality of core veneer in this area is excellent, with wood density ranging from 600 to 700 kilograms per cubic meter

Acacia core veneer

Eucalyptus core veneer

Rubber tree core veneer

Acacia and Eucalyptus are widely cultivated in Vietnam’s North Central Coast and South Central Coast regions. These trees significantly boost the local forestry industry. In contrast, the Central Highlands (Gia Lai, Dak Lak, Kon Tum) are dominated by Rubber trees. Rubber trees deliver substantial economic value and high production yields. Besides their economic importance, these plantations help control soil erosion. They also provide wildlife habitats, enhancing the ecological value of these regions.

Major production areas

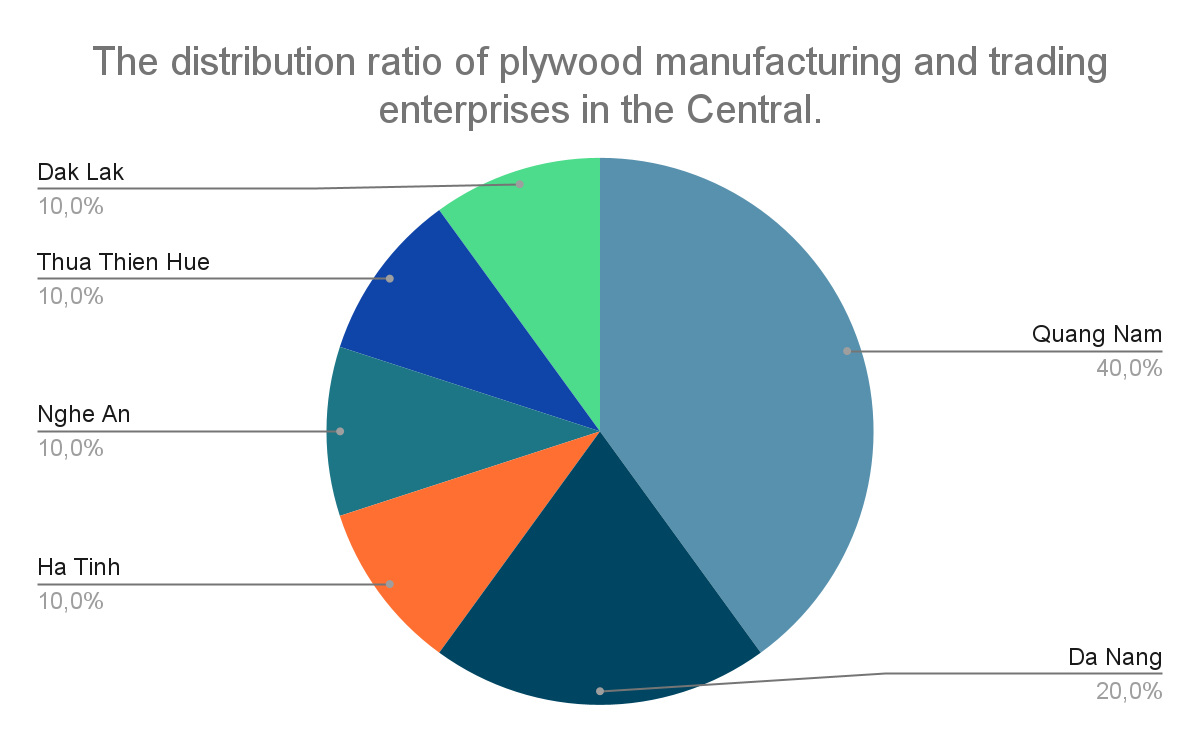

According to data from Vietnam Yellow Page, Quang Nam, Da Nang, Ha Tinh, Nghe An, Thua Thien Hue, and Dak Lak provinces concentrate plywood production in the Central region. Plywood production and business in Central Vietnam mainly occur in the North Central Coast and South Central Coast regions, where provinces adjacent to the coast benefit from convenient transportation routes for export.

Plywood factories in the Central region typically operate on a small to medium scale. However, larger industrial zones in Quang Nam have significant plywood manufacturing facilities. These facilities are equipped with advanced machinery, producing high-quality products at competitive prices. Large-scale operations benefit from economies of scale and advanced production technologies. This enables them to meet higher quality standards and achieve production efficiencies. Additionally, an extensive network of international seaports, including Quy Nhon Port, Da Nang Port, and Cua Lo Port, enhances transportation and export activities. This network facilitates seamless access to global markets.

Benefiting from the availability of raw materials like Acacia, Eucalyptus and Rubber tree, Central Vietnam is famous for good quality plywood and reasonable prices. The region’s strong products are: Film Faced Plywood, Commercial Plywood, Packing Plywood, Container Flooring Plywood

Characteristics of Plywood Production

The Central region of Vietnam has several strengths that contribute to its plywood production industry:

- Abundant raw material supply: The region is rich in forest resources, particularly Acacia, Eucalyptus, and Rubberwood. These plantations provide a steady supply of high-quality raw materials for plywood production, minimizing the need for imports and reducing costs.

- Strategic location and logistics: The region’s proximity to major national highways and international seaports such as Quy Nhon Port, Da Nang Port, and Cua Lo Port enhances the efficiency of both importing raw materials and exporting finished products.

(Image: Classifying core veneer)

However, the Central regions face several natural and internal challenges in advancing the plywood industry to a new level:

- Natural disaster and climate risks: The Central region frequently encounters extreme weather events such as storms, floods, and droughts, which damage plantation forests and disrupt industrial wood production.

- Small-scale and fragmented production: The production remains small-scale and fragmented, preventing optimal resource utilization.

In conclusion

In summary, while the plywood production scale in the Central region is small to medium-sized, it plays a vital role as a crucial raw material supplier for the major production hubs in the Northern and Southern regions.

Plywood from the Central region is renowned for its high quality, durability, and competitive pricing. This reputation is bolstered by the region’s access to abundant and premium raw materials, and efficient logistics network.