When embarking on a woodworking project, choosing the right material is crucial for ensuring the quality, durability, and aesthetics of your creation. Among the most popular materials used are plywood and medium-density fiberboard (MDF). While both have their unique advantages and applications, understanding their differences can help you make an informed decision for your next project. This article delves into the characteristics, benefits, and drawbacks of plywood and MDF, providing a comprehensive comparison to guide your choice.

Understanding Plywood

What is Plywood?

Plywood is a type of engineered wood made by gluing together thin layers of wood veneers. These veneers are typically arranged with their grains running perpendicular to one another, which enhances the material’s strength and stability. Plywood is available in various grades and thicknesses, making it suitable for a wide range of applications.

Characteristics of Plywood

- Strength and Durability: The cross-grain structure of plywood gives it exceptional strength and resistance to cracking, warping, and shrinking. This makes it an ideal choice for structural applications such as flooring, roofing, and wall sheathing.

- Versatility: Plywood comes in different grades, each suited for specific uses. For instance, A-grade plywood has a smooth, sanded surface suitable for cabinetry and furniture, while C-grade plywood is rougher and better suited for construction purposes.

- Water Resistance: While not all plywood is waterproof, marine-grade plywood is designed to withstand moisture and is used in boat building and other applications where water exposure is likely.

- Aesthetic Appeal: Plywood with a high-quality veneer finish can be used for visible surfaces in furniture and interior design, offering a natural wood look.

Applications of Plywood

Plywood’s strength and versatility make it suitable for a variety of applications, including:

- Construction (flooring, walls, and roofing)

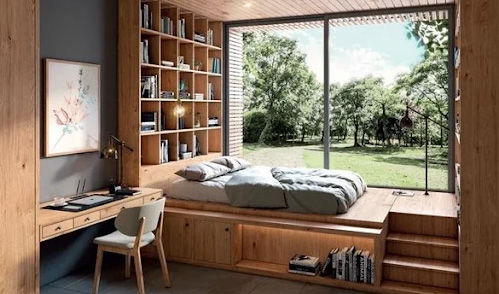

- Furniture making (cabinets, tables, and chairs)

- Interior design (wall panels and decorative elements)

- Boat building (marine-grade plywood)

Advantages of Plywood

- High Strength: Suitable for structural applications.

- Variety of Grades: Different grades cater to various needs.

- Aesthetic Options: Can have a natural wood finish.

- Water Resistance: Available in water-resistant forms.

Drawbacks of Plywood

- Cost: High-quality plywood can be expensive.

- Weight: Plywood is heavier than MDF, which can be a consideration in some projects.

- Edge Finishing: Edges can be rough and may require additional finishing.

Understanding MDF

What is MDF?

Medium-density fiberboard (MDF) is an engineered wood product made from wood fibers combined with wax and resin binders. The mixture is then compressed under high pressure and temperature to form dense, flat panels. MDF is known for its smooth surface and uniform density.

Characteristics of MDF

- Smooth Surface: MDF has a consistent texture and smooth surface, making it ideal for painting and veneering. This quality makes it a popular choice for decorative projects.

- Ease of Machining: MDF can be easily cut, drilled, and shaped without splintering, making it highly versatile for detailed woodworking projects.

- Cost-Effective: MDF is generally less expensive than plywood, making it an economical choice for many applications.

- Dimensional Stability: MDF does not expand or contract as much as solid wood or plywood, reducing the risk of warping and cracking.

Applications of MDF

MDF is widely used in:

- Furniture making (shelves, cabinets, and drawers)

- Interior design (wall panels, moldings, and decorative elements)

- Speaker boxes (due to its acoustic properties)

- Doors and door panels

Advantages of MDF

- Smooth Surface: Ideal for painting and finishing.

- Affordable: Generally cheaper than plywood.

- Easy to Work With: Can be machined easily without splintering.

- Stable: Less prone to warping and cracking.

Drawbacks of MDF

- Weight: MDF is dense and heavy, which can be a drawback in some applications.

- Water Sensitivity: MDF is not as water-resistant as plywood and can swell or deteriorate when exposed to moisture.

- Strength: While strong, MDF is not as structurally robust as plywood and may not be suitable for heavy-load applications.

- Health Concerns: Cutting or sanding MDF releases fine dust particles, which can be harmful if inhaled. Proper protective equipment and ventilation are essential.

Plywood vs. MDF: A Comparative Analysis

Strength and Durability

Plywood is generally stronger and more durable than MDF, especially for load-bearing applications. The cross-grain structure of plywood enhances its resistance to cracking and warping, making it suitable for structural uses. MDF, while dense and stable, lacks the same level of strength and may not be ideal for applications requiring high durability.

Surface and Finish

MDF offers a smooth, uniform surface that is perfect for painting and veneering. This makes it an excellent choice for decorative projects where a flawless finish is desired. Plywood, on the other hand, can have a natural wood grain that is visually appealing but may require additional finishing for a smooth surface.

Workability

Both plywood and MDF are easy to work with, but MDF has the edge in terms of machining. MDF can be cut, drilled, and shaped without splintering, allowing for intricate designs and detailed work. Plywood, while still workable, may require more care to avoid splintering and ensure clean cuts.

Water Resistance

Plywood, especially marine-grade plywood, is more water-resistant than MDF. This makes plywood a better choice for applications where moisture exposure is a concern. MDF can swell and deteriorate when exposed to water, limiting its use in damp environments.

Cost

MDF is generally more affordable than plywood, making it a cost-effective choice for budget-conscious projects. However, the lower cost comes with some trade-offs in terms of strength and water resistance.

Environmental Impact

Both plywood and MDF have environmental considerations. Plywood is made from natural wood veneers, which can be sourced from sustainably managed forests. MDF is made from wood fibers, which can include recycled wood, making it a more sustainable option in some cases. However, MDF production involves the use of resins and adhesives that can emit formaldehyde, a potential health concern.

Conclusion

Choosing between plywood and MDF depends on the specific requirements of your project. Plywood’s strength, durability, and natural aesthetic make it ideal for structural applications and visible woodwork. MDF’s smooth surface, ease of machining, and affordability make it perfect for decorative projects and detailed woodworking.

By understanding the characteristics, advantages, and drawbacks of each material, you can make an informed decision that aligns with your project’s needs and budget. Whether you opt for the robust nature of plywood or the versatile qualities of MDF, both materials offer unique benefits that can enhance the quality and functionality of your woodworking projects.