Just like common industrial woods such as chipboard, MDF, HDF, plywood can be coated with a variety of coating surfaces to increase its value when applied to the interior.

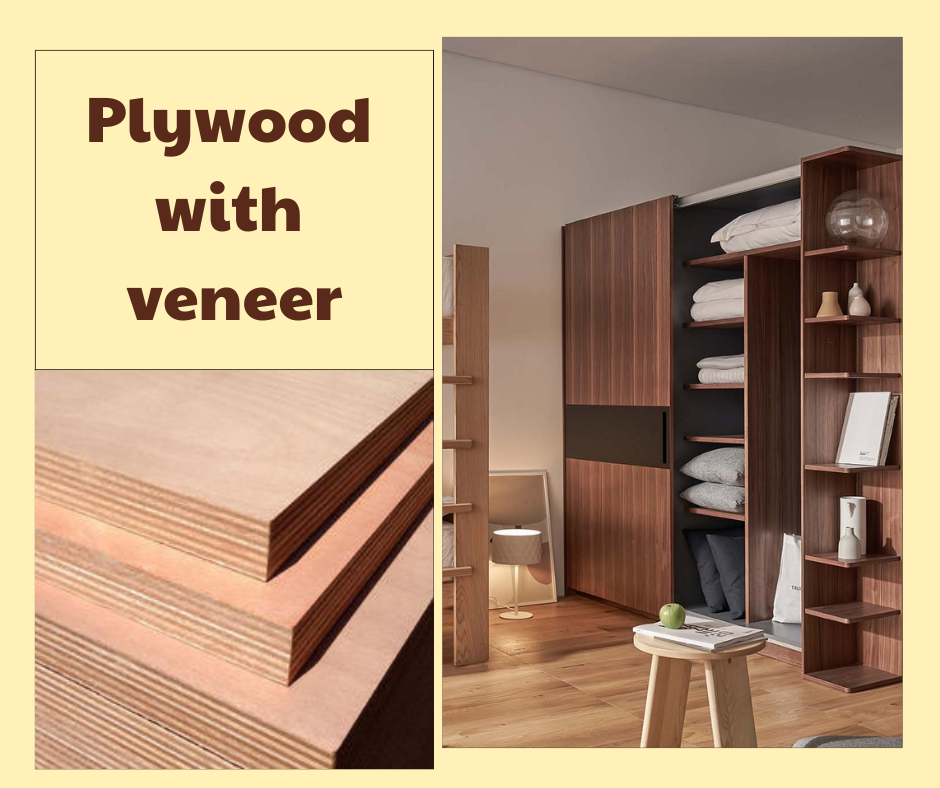

1.Veneer coated plywood

Veneers are thin slices of wood, usually thinner than 3mm. They are used to affix to core panels to produce flat details, such as doors, floors, and furniture parts. This surface is highly appreciated for its aesthetic value. Veneers maintain the original beauty of natural wood. At the same time, they solve economic problems by being much cheaper than solid wood.

In fact, plywood cores are also made from veneers. The wood layers are arranged perpendicular to the wood grain direction. They are bonded together with adhesive during pressing at standard temperatures and pressures. Therefore, ordinary plywood panels already have a veneer surface. However, when used for interior applications, the top veneer layer must have high quality and aesthetic value. The surface layer may be made from specific types of wood, such as oak or walnut, depending on the interior design requirements.

2. Laminated plywood

Laminate, also known as HPL (High-Pressure Laminate), consists of three layers:

- Overlay layer: This is a layer of pure cellulose applied on top to create a glossy finish. It has properties such as scratch resistance, impact resistance, and resistance to chemicals, as well as protection against environmental and everyday wear and tear.

- Decorative paper layer: This is a layer of decorative paper impregnated with melamine glue. It is crucial for the aesthetic appearance of laminate. Under high temperature and pressure during pressing, the overlay layer melts and adheres tightly to the paper beneath, ensuring stable colors in the laminate.

- Kraft paper layer: This layer consists of multiple sheets of kraft paper compressed together, forming the base of the laminate. The thickness of the laminate is primarily determined by these layers. Therefore, laminate can be used independently without being pressed onto a plywood core.

3. Melamine-Coated Plywood

Melamine-coated plywood is a type of plywood with a core made from plywood and a surface covered with melamine. Melamine is a thin decorative paper impregnated with melamine urea formaldehyde (MUF) glue.

Melamine is a highly regarded surface for interior plywood. The decorative paper is pre-printed with patterns and colors, enhancing the aesthetic appeal of the plywood and protecting the furniture from external impacts to the wood core.

Compared to most other surface materials, melamine is a more cost-effective option due to its reasonable price and diverse design options. Although plywood has been around for a long time, it was traditionally used mainly in construction and packaging due to its limited aesthetic appeal. Coating plywood with melamine represents a significant advancement, increasing the value of this type of engineered wood in everyday life.

Melamine-coated plywood is mainly used in three primary areas: ceilings, wall paneling, and furniture products. In many countries around the world, such as Japan, South Korea, and the United States, the demand for this material is increasing. As a result, the production of melamine-coated plywood and furniture is opening up significant opportunities for the interior materials industry.

4. Film Faced Plywood

Film-coated plywood is a type of plywood that has a layer of film applied to both surfaces. This film is a paper layer impregnated with a special phenolic waterproof adhesive. It enhances durability, increases load-bearing capacity, and reduces external physical impacts on the product.

The plywood core is made from multiple thin layers of wood bonded together using WBP (Weather and Boil Proof) phenolic glue. The core’s construction increases strength and minimizes warping, swelling, or shrinking.

The combination of a plywood core, film surface, and waterproof glue is achieved through hot pressing at temperatures ranging from 125°C to 140°C. This results in film-coated plywood with superior quality. With its distinctive and outstanding features, film-coated plywood is an essential component in modern construction projects. It is also known by other names such as formwork plywood and film-faced formwork plywood.

In addition to UV-coated plywood, many other surfaces are also well-known. However, the types of plywood mentioned above are the most popular in the Vietnamese market.

With its outstanding properties, plywood is widely used in daily life and home interiors. Moreover, plywood is an ideal material to replace natural wood, which is currently very scarce on the market. Why is plywood so popular? Find out more at: https://vietnamplywood.vn/top-4-popular-plywood-usage/

We hope that the information shared about plywood in the above article has given you a clearer understanding of this type of plywood material. This will help you make the right choice when selecting furniture for your home.